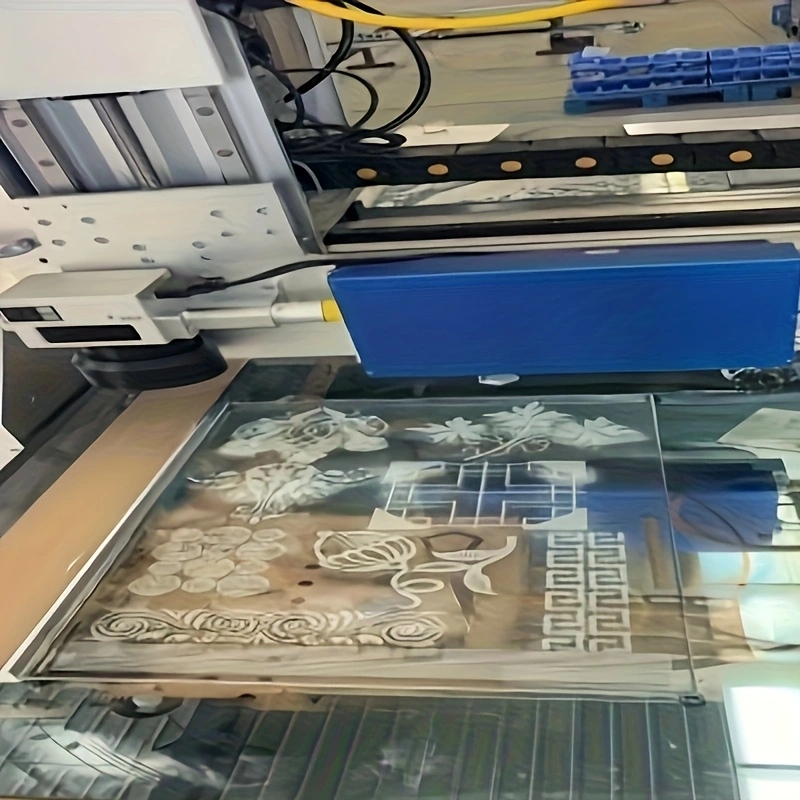

This cutting-edge industrial equipment perfectly integrates the precision of laser technology with the efficiency of sandblasting. Equipped with an advanced laser control system, it utilizes a finely tuned laser beam to precisely regulate every detail of the sandblasting process—whether in terms of scope or depth—achieving unprecedented accuracy. This level of control ensures exceptional finesse and consistency, making each treatment as precise as a work of art.

The machine excels in material versatility, effortlessly handling metals, plastics, and glass. It also demonstrates remarkable capability in processing intricate shapes and micro-scale areas. Thanks to its flexibility and precision, the laser sandblasting machine has become an indispensable tool in industrial surface treatment. It meets a wide range of processing needs, from simple to highly complex, empowering engineers and designers to turn creativity into reality and produce both aesthetically pleasing and highly functional products.

Product features

- Adopt the latest generation of laser control software, which is simple to operate and powerful.

2.The whole machine adopts Yadek linear guide rail, 1400MM length, 1.5 die rack

3.The optical path components use high-speed, high-precision 12-spot galvanometer lens and telecentric quartz mirror to form the optical path part.

4.The cooling part uses a dual-temperature dual-control chiller to control the temperature of the laser to ensure that the equipment can work well for a long time.

5.The equipment adopts industrial aluminum profile gantry structure, high-strength welded frame, overall stress relief treatment, good rigidity and small deformation.

6.The whole machine is welded steel structure, annealed and processed by 5-axis CNC milling to ensure the overall operation accuracy.

7.The whole machine running parts are all processed by industrial aluminum profile 5-axis machining center to ensure the accuracy of the overall operation of the equipment.

8.Equipped with high-precision servo motor drive and transmission mechanism, high precision, large transmission torque, small transmission error, and good dynamic characteristics.

9.Adopt a new high peak fiber laser (Moke customized model), with a good beam, high power stability, low power consumption, and long life.

10.The Z-axis worktable can be automatically raised and lowered to provide high-quality processing for plates of different thicknesses and materials, with few failure points and high stability.

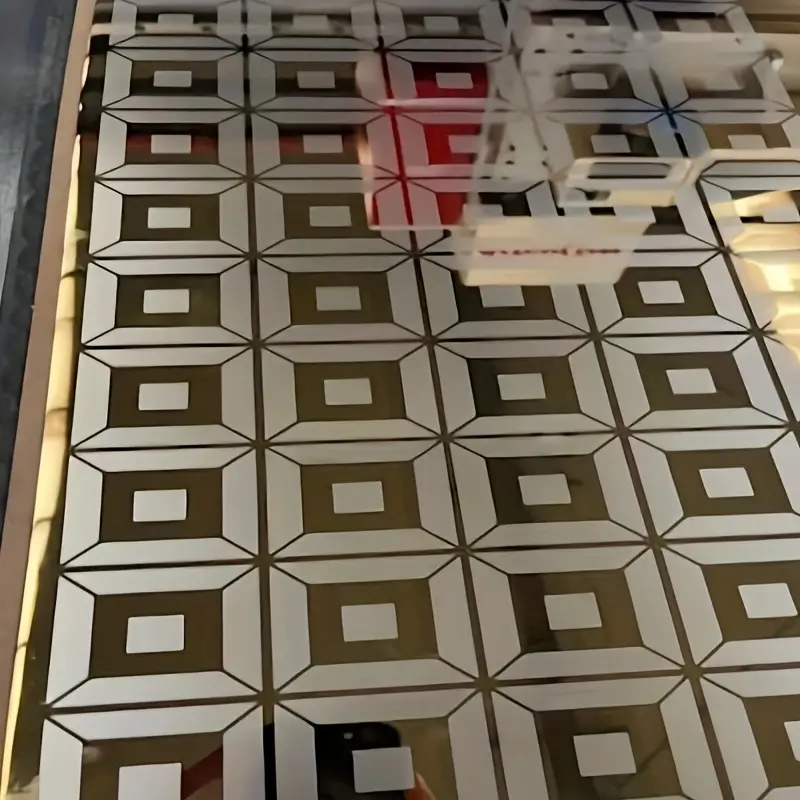

PVC Tabletop

- Laser Sandblasting Machine-MK1124

- Laser Sandblasting Machine-MK1530

- Laser Sandblasting Machine-MK2030

- Laser Sandblasting Machine-MK2436

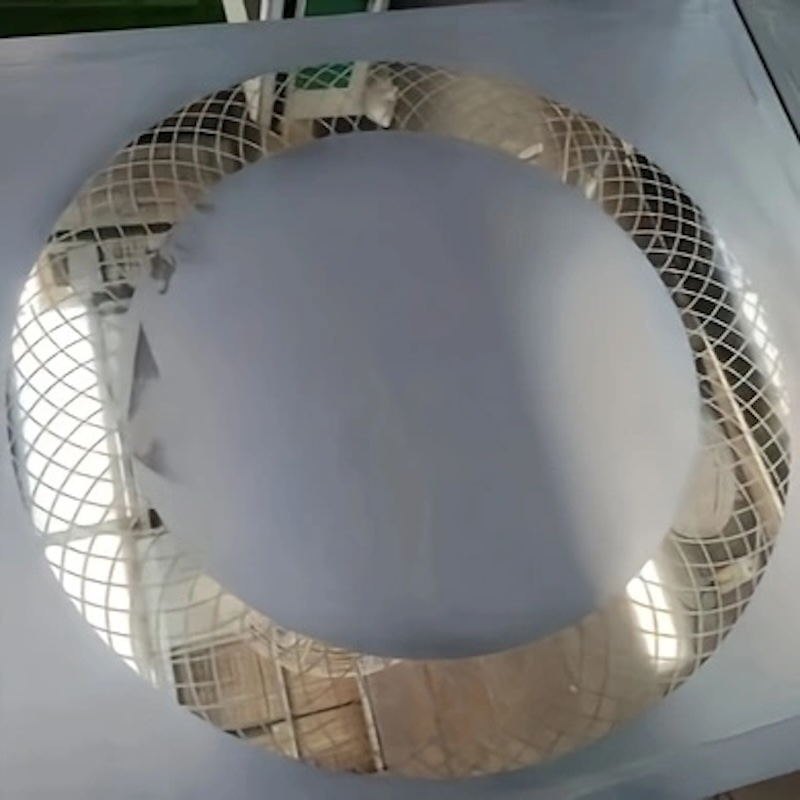

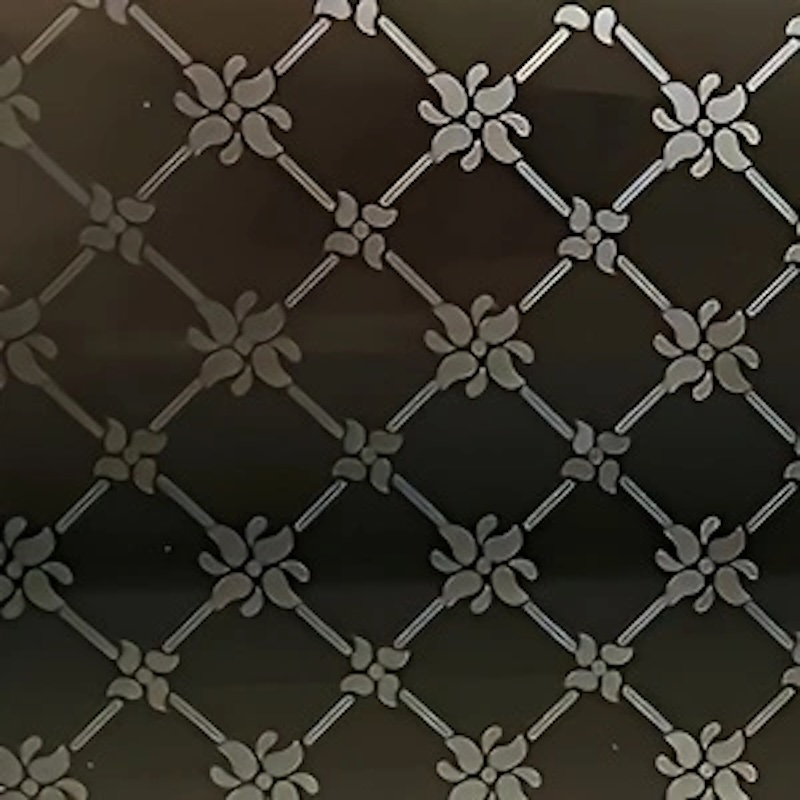

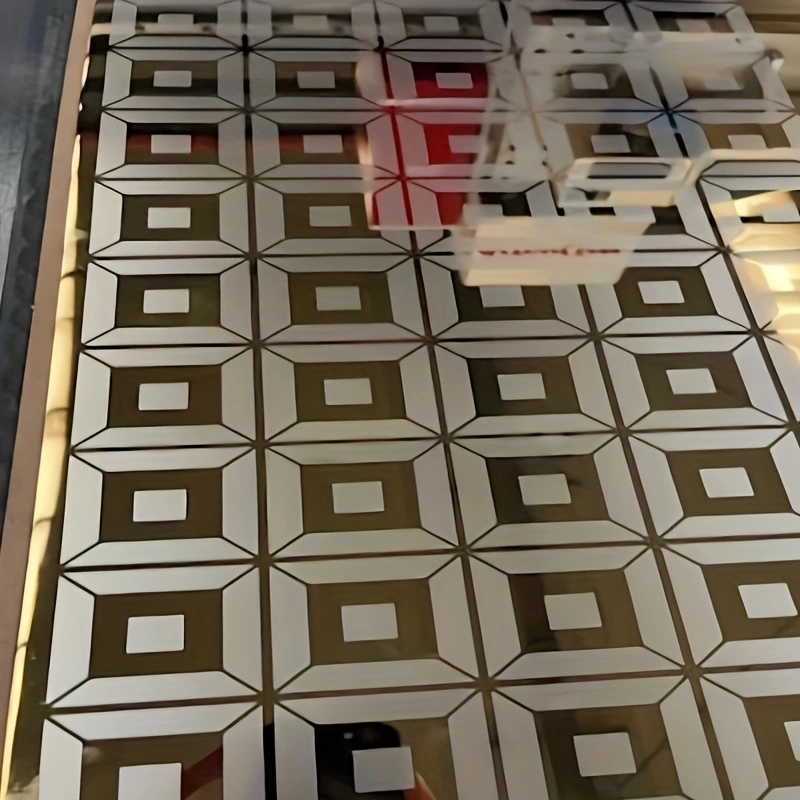

Product Shows

Product Video

| Machine basic parameters | |

| Machine model | MK1224/MK1530/MK2030/2436(50W/100W/140W/200W) |

| Working mode | Fiber Laser |

| Working size | 10*10*3–1200*2400*50MM |

| Floor space | 3100*2100*800MM |

| Weight | 950KG |

| Machine technical parameters | |

| Total power | 4KW |

| Laser | High Peak Fiber Laser |

| Laser power | 140W/200W (Moke customized laser) |

| Theoretical life of laser | About 80,000 hours |

| Optical maser wavelength | 1055-1070nm |

| Engraving range | 60*60mm |

| Mechanical repeatability | ≤±0.25mm |

| Laser repetition accuracy | ≤±0.002mm |

| Engraving line speed | ≤12000mm/s |

| Motor system | CW laser system (Taiwan) |

| Smoke exhaust system | High pressure fan flue direct exhaust |

| Work power | AC190-240V . 50-60HZ |

| Work Environment | +5—35℃ Relative humidity 30 – 60% |

| System and software | ||

| Computer and system software | Microsoft Windows98、2000、XP、win7 64bits control system/win10 | |

| Designs of software | Microsoft Windows 98、2000、XP、win7 64bits control system/win10 Auto CAD、Corel DRAW、type3、wentai | |

| Graphic format | EPS、DXF、PLT、CDR、AI、AC6 | |

| Laser technical parameters | ||

| Modulation frequency range | 20Hz-2000Hz | |

| Spot diameter | ±3.5mm | |

| Power Stability(Average power) | ≤3%rms | |

| Power stability (Peak power) | ≤5%rms | |

| Optical quality | M2<1.35 | |

| Scanning head technical parameters | ||

| Maximum line speed | 12000mm/s | |

| Marking character speed | 200 characters/second, Roman font, character height 1mm | |

| Resolution | 5pm | |

| Repeat marking accuracy | ±0.003mm | |

| Min. marking width | 0.012mm | |

| Min. character height | 0.15mm | |

| Marking depth | ≤ 0-1mm | |

| Marking range | 60*3000mm & Customizable | |

| Working focus | 150±2mm (75*75MM) | |

| Cooling equipment | Dual-control water chiller, water temperature 25-28 degrees | |

| Maintenance | Maintenance-free | |

| Mechanical part | |

| Processing thickness | 1~50mm |

| Processing parallelism | ≤±0.25mm |

| Processing speed | 0~10 meter/min |

| Scanning engraving speed | 0-12000mm/s |

| Laser | Fiber Laser |

| Oil supply | Manual oil injection system |

| Fixed device | optional vacuum suction device |

| Platform plate | high density PVC board.(flatness ≤±0.40mm/m). Durable to use |

| Rack/guide rail | Square rail/helical gear adopts domestic well-known brand motor, drive and guide rail, which ensures the stable performance of the machine, high precision and long service life |

| Vibration lens | Jinhaichuang fixed type |

Main parts of equipment

| Galvanometer lens | Jinhai chuang | The durability is twice that of ordinary domestic products | |

| Field Lenses & Beam Expanders | Telecentric field lenses | ||

| Guide Rails & Slides Bearing | Made in China Made in China | High hardness High hardness | |

| Other electrical appliances such Delixi | |||

| as switches/filters, etc. | |||

| Rack | Made in China, 1.5 die rack | High hardness and high precision | |

| Laser control system | Taiwan | Round rectangle adaptive | |

| Photoelectric positioning | Shanghai Hugong | automatically find the edge and position | |

| Cable | Shanghai Cardiff | Special flexible cable | |

| Computer | Laser matched | ||

| Servomotor | Taiwan | Dual drive, four motors(three 750W and one 400W) | |

| Crossbeam | Seamless steel | Customized | |

| The machine body | One-piece welding | After fire aging treatment, it will not be deformed permanently | |

| Oil-water over pressurizer | Manual oil injection system | Manual lubrication to avoid freezing in winter and prolong the service life of the equipment | |

| Software Section | |

| Professional laser control processing software | High-precision Taiwan professional laser control system, used under WINDOWS operation interface (convenient for drawing and operation) and compatible with drawing software such as Wentai Engraving, CorelDRAW, AUTO CAD, etc. |

| Scan path selection function | Ensure the best processing efficiency |

| Origin complement function | Secondary device origin |

| Operation input | Keyboard and mouse, Chinese dialogue interface |

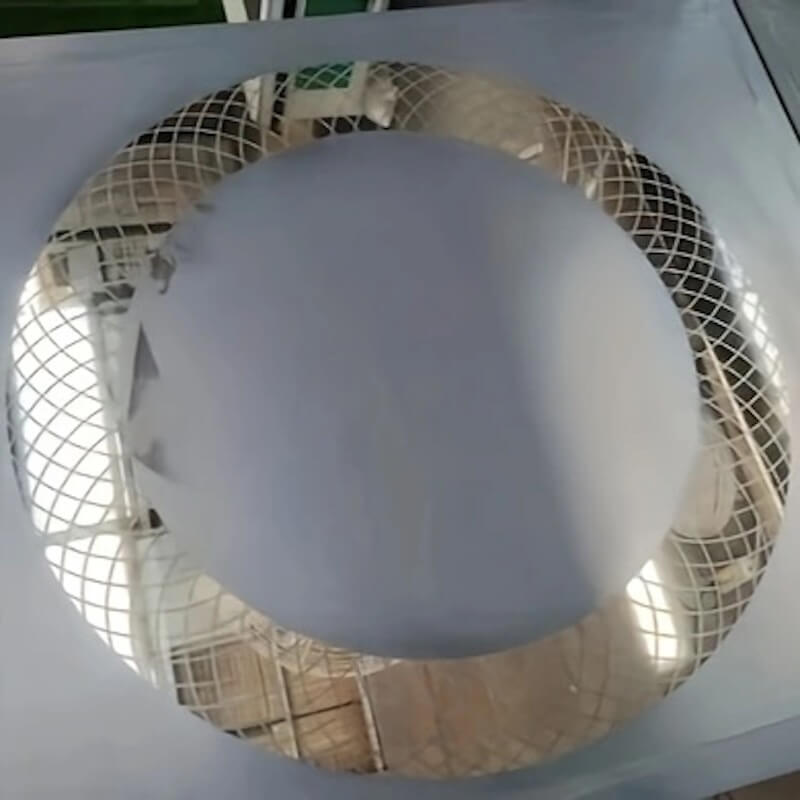

Hollow-cut tabletop

- a:Standard Hollow-cut Edition Tabletop

- b:Custom Hollow-cut Edition Tabletop