The intelligent fully automatic glass cutting line consists of three systems: loading, cutting, and breaking. It integrates automatic loading, automatic optimization layout, automatic labeling, automatic conveying, and air-floating breaking table. It can be equipped with laser marking, Low-e film removal and other functions. The intelligent cutting line has the advantages of good stability, safety, convenience, labor saving and higher efficiency, and provides straight and special-shaped cutting of glass. It is suitable for glass cutting operations in architecture, decoration, home appliances, mirrors, handicrafts, etc. It has professional glass cutting and optimized layout functions, which greatly improves the glass cutting rate and production efficiency. It is compatible with the standard G code of Italian OPTIMA optimization software and domestic Guiyou software, and realizes the versatility of processing files in different formats. Fault diagnosis and alarm function: It can automatically record the machine operation status during the production process, alarm faults and display problems. Glass automatically finds the edge and positions, accurately detects the actual position and deflection angle of the glass, and automatically adjusts the cutting path of the cutter head to improve efficiency. Intelligent special-shaped scanning, the detector can intelligently scan special-shaped objects and feedback automatically generate graphics to achieve contour cutting. The cutting head pressure is controlled by a mechatronic precision pressure valve. The cylinder outputs pressure evenly so that the cutting head fits the glass surface perfectly for cutting, thus avoiding the phenomenon of cutting head jumping due to glass quality problems.

Product features:

- The equipment and computer linkage closed-loop, high-precision andhigh-speed cutting.

Fool-like operation,straight cutting, profiled cutting.

3.With automatic laser positioning, graphics scanning and other latest features. - After the glass is cut, three synchronous belts cooperate with the air flotation system to transport the glass to the air flotation breaking table for breaking.

- The cutting table is equipped with air flotation holes, and the centrifugal fan provides high-pressure airflow to facilitate the transportation of glass and protect the table.

- Instead of manual labeling, the printer automatically prints out labels that record glass information, and the labeling cylinder fingers grab the labels and stick them on the corresponding glass surface.

- Head labeling: replaces the old side labeling, with fast labeling speed, greatly improving production efficiency.

- Laser marking and automatic labeling can be switched as needed to meet diverse production needs. It can mark at high speed and with high precision and can print QR codes, 3C certification, logos, etc.

- The grinding wheel motor adopts the servo motor of Fuji of Japan, which has the advantages of small structure, fast starting speed, large torque, stable and reliable operation

- The machine comes with a vacuum cleaner to prevent dust pollution

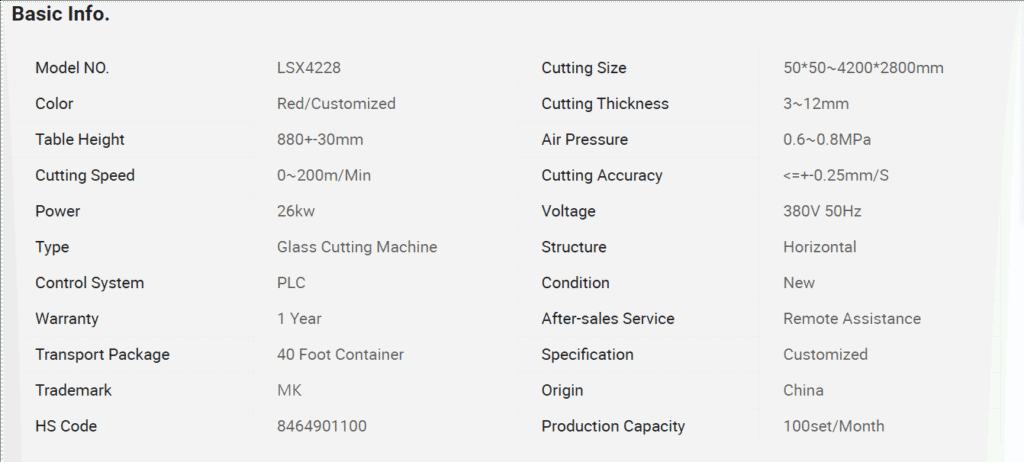

4228

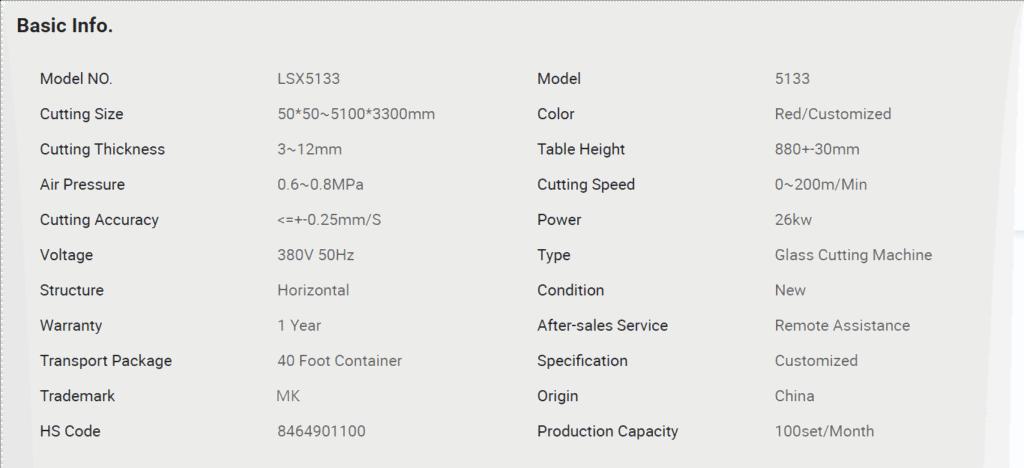

5133

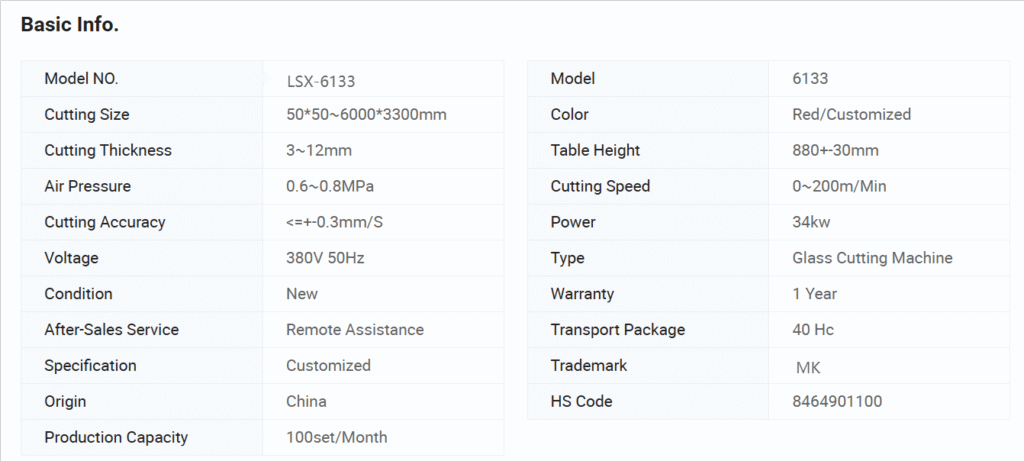

6133