Advantages

1. Small footprint, simple and safe operation

2. The fastest speed is 180m/min, high precision, labor-saving, can be controlled by PLC, walk around the workshop, 360 degrees rotation,

3. The table is made of high-hardness nylon plate with good flatness, moisture-proof during sea transportation, and 4. The X-axis and Y-axis tracks use linear guides, ground racks, and good stability

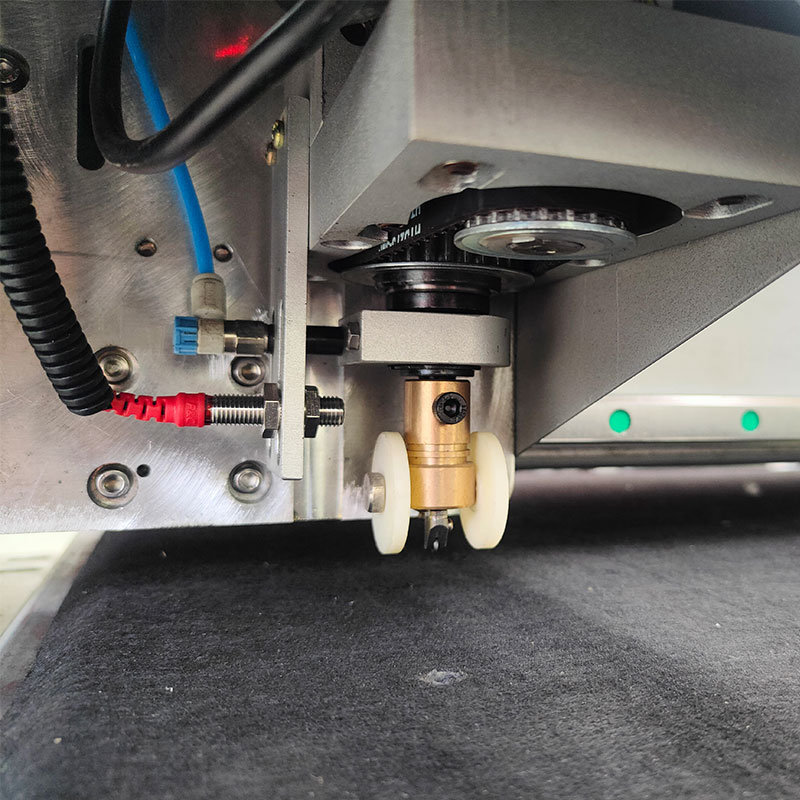

5. The knife wheel uses a high-hardness knife wheel with a protective device to prevent knife collision. Automatic transmission, automatic labeling and breaking can be installed to form an assembly line operation.

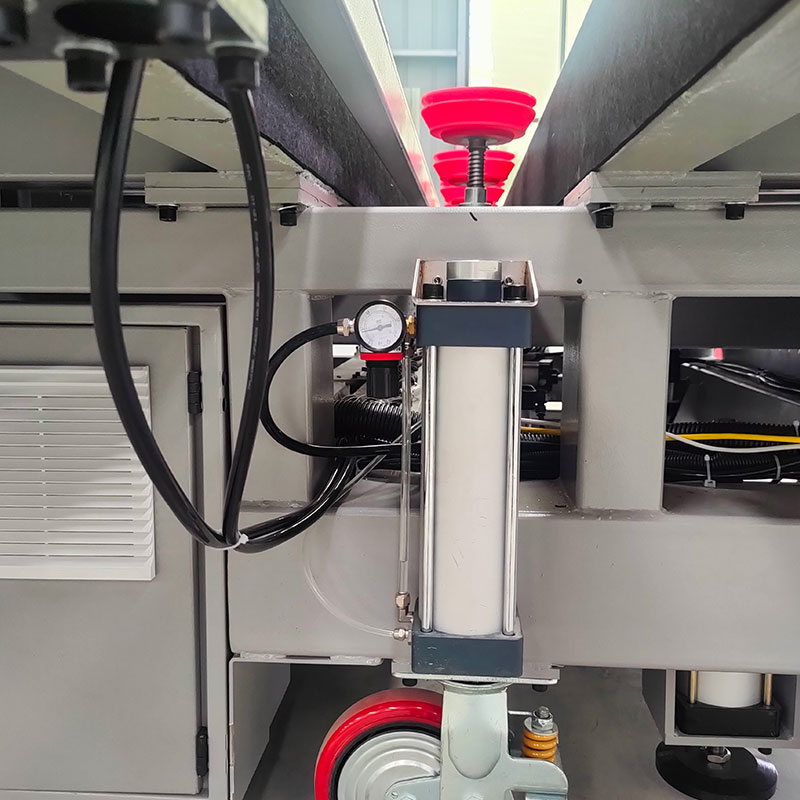

6. Mobile device inside the machine,which can be moved to any glass location for loading, cutting, breaking.

7. through a remote control device to operate the device, effectively avoid personal injury and property damage likely to result from, the equipment itself also has a computer to automatically detect electrical protection devices, make the equipment very simple and safe to use.

8. one person who can complete loading, cutting, breaking,. Meanwhile workers through remote control operation without contact glass, completely eliminate this aspect of high security risks, using flexibility can be applied to different sizes of glass, a piece of equipment has the function of multiple devices.

Working process

1. Work flow: After starting the inputting machine, arms automatically suck glass from the shelf. Under sensor controlled, glass automatically find glass edge in the X and Y directions. After moving glass sheets to designated location, transport glass to the automatic cutting table.Cutter will move to coordinate origin, and automatically start to cut according to the preinstall graph.

2. The operator can edit the glass size for cutting with computer. The computer can optimize the cutting size, and give out the data for processing.

Product Video

Product Packing

MK-3628 parameter

| Model | MK-3628 |

| Dimensions | 3600*4000*1400mm |

| Table size | 2500*3800*850mm |

| Workbench height | 880mm |

| Maximum size of cut glass | 3660*2800mm |

| Cutting thickness | 2-19mm (Automatic adjustment) |

| Cutting speed | 0-160m/min |

| Input voltage | 380V/50HZ |

| Loading speed | 16-40s |

| Installed power | 12.8kw |

| Machine weight | 4100KG |

MK-2420 parameter

| Model | MK-2420 |

| Dimensions | 2700*3000*880mm |

| Table size | 2500*2500*880mm |

| Workbench height | 880mm |

| Maximum size of cut glass | 2440*2000mm |

| Cutting thickness | 3-19mm (Automatic adjustment) |

| Cutting speed | 0-180m/min |

| Input voltage | 380V/50HZ 0.6MPA |

| Loading speed | 15-40s |

| Installed power | 11kw |

| Machine weight | 2600KG |