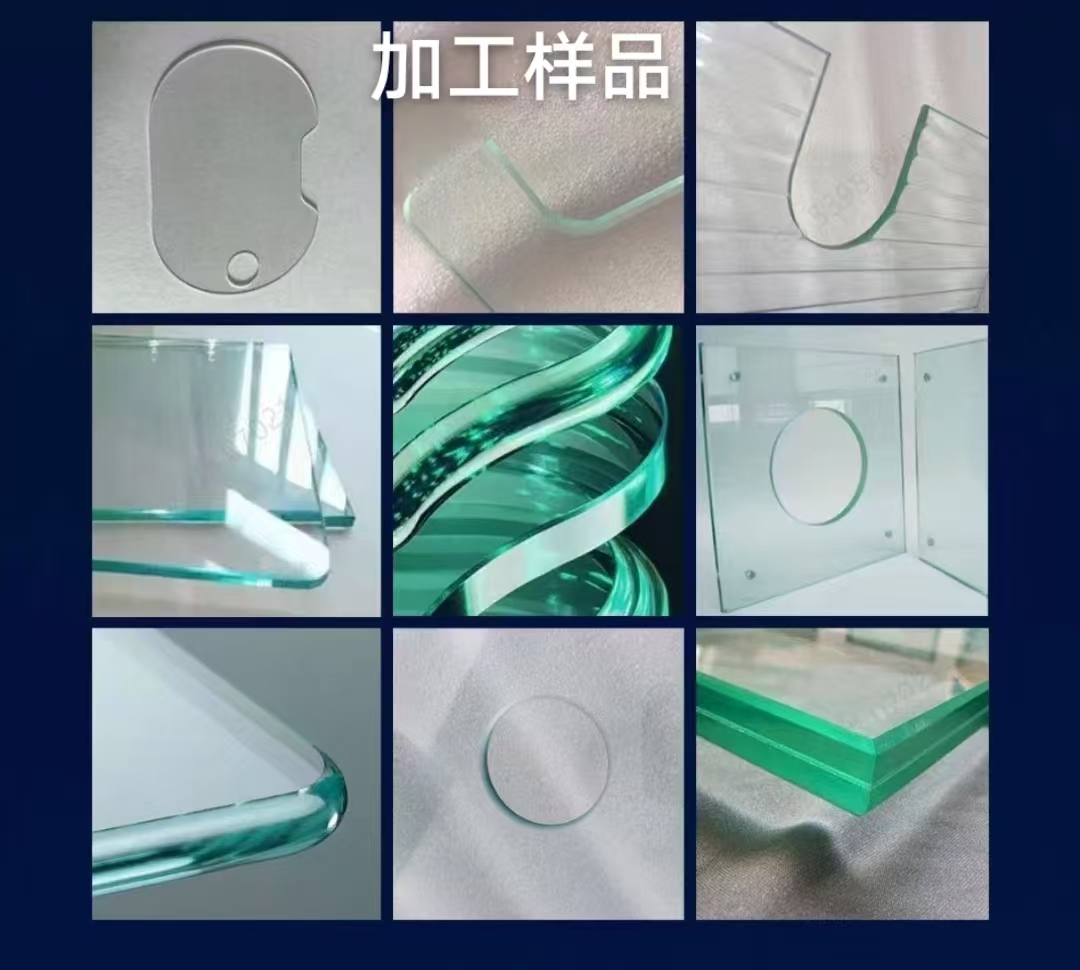

ZXX-C series glass machining center is the company’s leading product. It has part of the function of a water jet machine, it can cut any shape, as you like, it can drill holes like a drill bit machine.lt It can grind and polish the edges of the glass, suitable for all different shapes of glass. At the same time, it can also engrave drawings on the glass surface like an engraving machine. With the integrated functions of drilling, cutting, milling, grinding, polishing, and engraving, once completed, there is no need to change the tool, effectively avoiding glass scratches and dimensional errors caused by repeated positioning.

advantage

1. CNC system, easy to use and intuitive, machine management and software control. It has powerful glass edge grinding, polishing, milling, grooving and drilling capabilities.

2. Electric spindle Heavy electric spindle has the characteristics of large torque output and high speed.

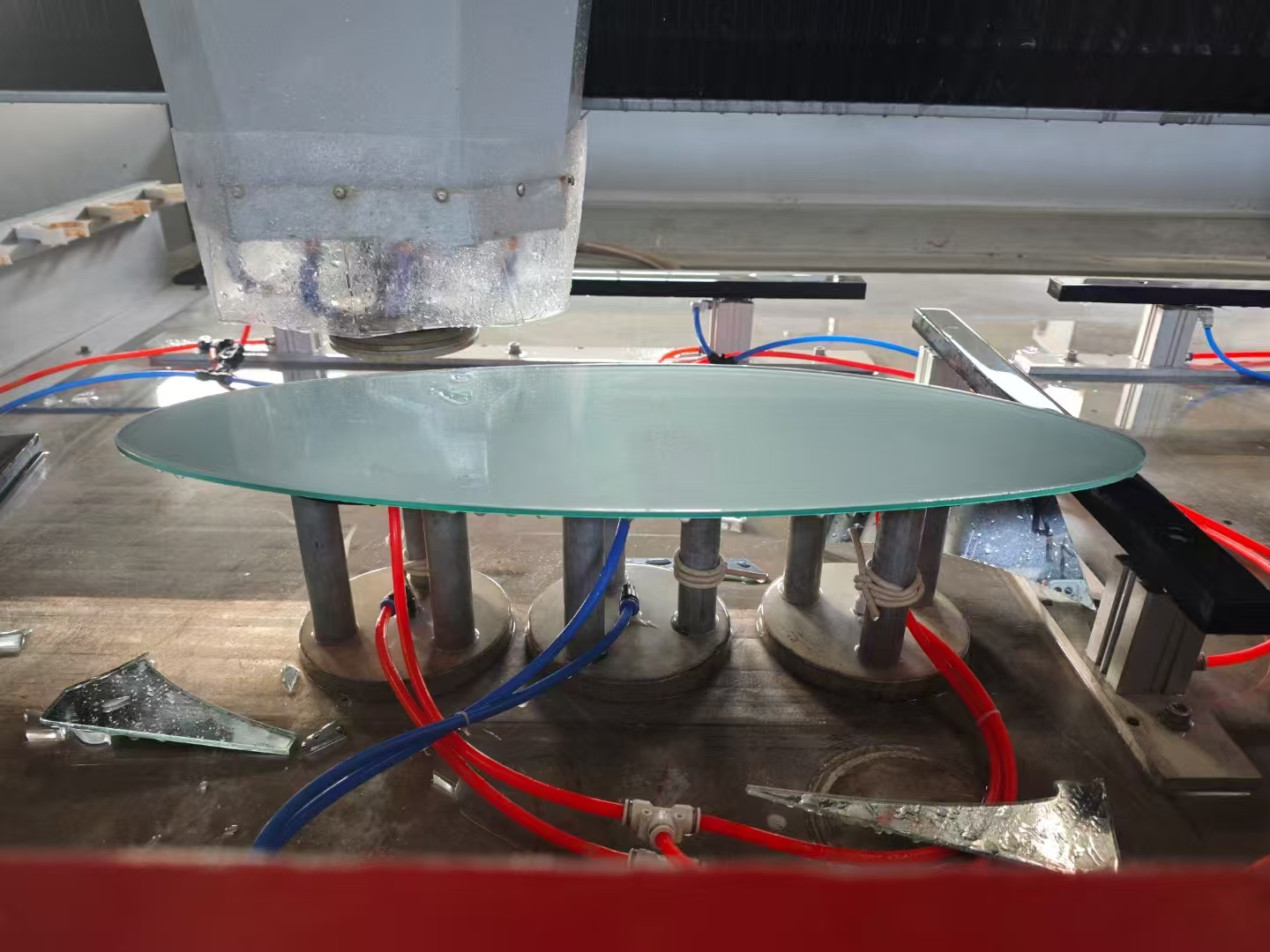

3. Different types of tablet clamping system The suction cup shrink and telescopic stop is fixed on the worktable through a vacuum circuit, which can position a variety of different shapes of glass for processing.

4. The automatic tool changer (optjonal) working unit can automatically take out the tool from the tool magazine for processing, so as to greatly reduce the tool change time. LDEA for Rapid Processing (LDEA)

5. There are sink holes in the cabinet glass countertop, stove hole, and pipe hole. Shower door clamps, hinge holes, handle holes, cutouts. Cabinet kitchen door invisible handle hole. Aluminium profile handle hole and hinge hole. Switchboard.

Main parameters:

| type | ZXX-C3018 type | apply | glass |

| Process usage | CNC unconventional machine tools | Movement mode | Linear control |

| Control method | Semi-closed-loop control | numerical control | CNC/multinational company |

| Machining accuracy | 0.05-0.1 (mm) | Performance classification | High-end CNC machine tools |

| authentication | that | condition | What’s new |

| structure | level | type | CNC machine |

| Control system | CNC, servo | Glass cleaning machine type | Waterjet |

| Types of glass edging machines | milling machine | Grinding head number | 2 |

| products | CNC glass machining center | function | Drilling, cutting, grinding, milling, engraving |

| thickness | 3-25 mm | drawing | CAD drawings |

| best | 2 | Processing speed | 0-20 m/min |

| Application 01 | Sink countertop on glass | Application 02 | Furnace holes, pipe holes |

| Application 03 | Shower door clamp, hinge hole, handle hole | Application 04 | The cabinet door is invisible Handle holes |

| Application 05 | Aluminium profile handle hole and hinge hole | Application 06 | switchboard |

| Application 07 | Aquarium invisibility cover | type | ZXX-C3018,2021,2513, 1812, 1015 |

| Volt. | 220V、380V、415V 450V /50Hz,60Hz | Transport packages | Standard export package |

| specification | 4000*2860*2200 mm | trademark | ZNXU |

| origin | China | HS code | 8464901900 |

| production capacity | 20 sets/month |

| commodity | unit | detailed |

| type | establish | ZXX-E0825 |

| Mach bed | establish | Heavy heat treated beds |

| Linyi | ||

| control system | establish | ZNXU |

|

spindle |

personal computer | Diameter: T1¢ 125 Cooling Method: Water Cooling |

| 24000 | ||

| 7.5 千瓦 | ||

| 桌子尺寸 | 毫米 | 750*2450 |

| 工作旅行 | 毫米 | 750*2450*280 |

| Z轴高度 | 毫米 | 280 |

| 机器内部 结构 | 套套 | 半盖/防水设计 |

| 工作台 load weight | KG | 450 |

| Position accuracy | mm | 0.1 |

| Repeated position.accurac y | mm | 0.1 |

| Empty move | m/mi | 50 |

| Commodity | unit | Details |

| MODEL | SET | ZXX-C2010 |

| Mach.Bed | set | Heavy heat treatment bed |

| LINYI | ||

| Control System | set | ZNXU |

|

Spindels |

pc | DIAM:T1 ¢ 150 Cooling method: water cooling |

| 12000 | ||

| 11KW | ||

| Worktable size | mm | 2000*1000 |

| Work | mm | 2000*1000*380 |

| Work travel | ||

| Z Axis height | mm | 380 |

| Internal of machine structure | set | Half cover/ waterproof design |

| Work table load weight | KG | 450 |

| Position accuracy | mm | 0.1 |

| Repeated position.accurac y | mm | 0.1 |

| Empty move speed | 米/分 m/mi n | 15 |

| Max Process Speed | 米/分 m/mi n | 磨<15m/min 抛<6m/min |

| Power request | KW | AC/380v/18KW/50HZ |

| Overall Size | mm | 2100x3300x2200 |

| N.W. | KG | 2400 |

| Energy consumption | KW.H | 18.6 |

| Commodity | unit | Details |

| MODEL | SET | ZXX-C2515 |

| Mach.Bed | set | Heavy heat treatment bed |

| LINYI | ||

| Control System | set | ZNXU |

|

Spindels |

pc | DIAM: ¢ 150 Cooling method: water cooling |

| 12000 | ||

| 15KW | ||

| Worktable size | mm | 1500*2500 |

| Work travel | mm | 1500*2500*380 |

| Z Axis height | mm | 380 |

| Internal of machine structure | set | Half cover/ waterproof design |

| Work table load weight | KG | 450 |

| Position accuracy | mm | 0.1 |

| Repeated position.accurac y | mm | 0.1 |

| Empty move speed | m/mi n | 50 |

| Max Process Speed | m/mi n | 磨<15m/min 抛<6m/min |

| Power requirements | KW | AC/380v/24KW/50HZ |

| Power request | ||

| Overall Size | mm | 2650x4100x2200 |

| N.W. | KG | 3600 |

| Energy consumption | KW.H | 24 |

| Commodity | unit | Details |

| MODEL | SET | ZXX-C3020 |

| Mach.Bed | set | Heavy heat treatment bed |

| LINYI | ||

| Control System | set | ZNXU |

|

Spindels |

pc | DIAM:T1 ¢ 150 Cooling method: water cooling |

| 12000 | ||

| 15KW | ||

| Worktable size | mm | 2000*3000 |

| Work travel | mm | 2000*3000*380 |

| Z Axis height | mm | 380 |

| Internal of machine structure | set | Half cover/ waterproof design |

| Work table loading | KG | 450 |

| Work table load weight | ||

| Position accuracy | mm | 0.1 |

| Repeated position.accurac y | mm | 0.1 |

| Empty move speed | m/mi n | 50 |

| Max Process Speed | m/mi n | 磨<15m/min 抛<6m/min |

| Power request | KW | AC/380v/24KW/50HZ |

| Overall Size | mm | 3300x4500x2200 |

| N.W. | KG | 3800 |

| Energy consumption | KW.H | 24 |