What is the working process of the glass cutting line? What does it consist of?

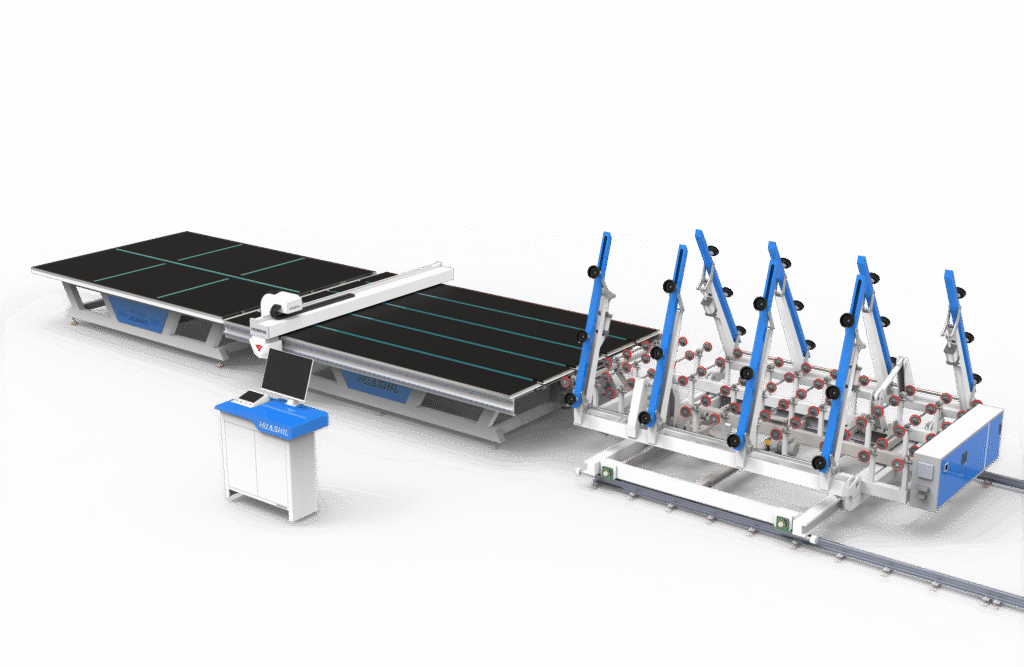

The glass cutting line adopts mechanical flipping, and the original glass to be processed is taken off the material rack through the vacuum suction cup and dropped onto the loading table. The glass is transported to the cutting platform through the rollers on the loading table and the conveyor belt on the glass cutting table. The knife box on the crossbeam of the cutting machine drives the tool to move at high speed in the X and Y directions through the servo motor, and uses the rotation of the Z-axis motor to control the tangent trajectory of the tool, and at the same time uses the analog quantity to control the knife pressure and knife depth. The four axes move simultaneously for cutting. When the cutting is completed, the glass is transported to the air-floating breaking table for breaking through the conveyor belt on the cutting table and the air flotation formed by the breaking table. It is mainly composed of eight parts: frame mechanism, flip mechanism, suction cup lifting mechanism, X-axis walking mechanism, Y-axis walking mechanism, conveying mechanism, vacuum and air path control system, and electrical control system.

What is the thickness and straight-line cutting accuracy of glass cut by the glass cutting line? What is the glass cutting speed?

The glass processing thickness is 3-19mm, the straight-line cutting accuracy is ±0.20mm/m, and the glass cutting speed is 0-200 meters/minute.

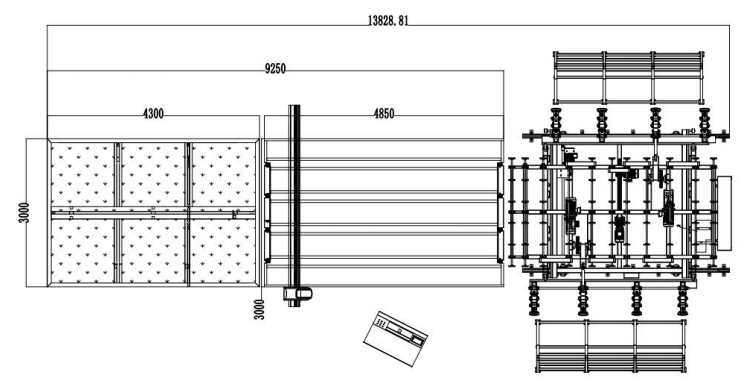

Can the size of the glass cutting line be customized?

We have dedicated technicians who will give reasonable suggestions based on the size of the customer’s factory and issue corresponding drawings for customer reference.

What is the difference between a glass cutting line and a glass cutting machine?

The glass cutting line is suitable for large-scale continuous production, with high efficiency. It is a fully automated equipment that realizes automatic loading, cutting, slicing and unloading of glass through conveyor belts, robotic arms, etc. The glass cutting machine is suitable for small-batch production and is suitable for customers pursuing large-scale production.

Is the installation of the glass cutting line more complicated?

According to the current conventional models 5133 and 6133, technology is required for installation. If the customer has rich experience and local technicians to help operate, we can provide remote technical guidance to help customers install.